From the cozy onesies of newborns to the rugged jackets worn by adventurers, a single small component often goes unnoticed yet plays a crucial role — the humble snap fastener. These tiny connectors have quietly stitched together functionality and fashion across generations. In this article, we'll take you on a journey through time, explore the anatomy of these fasteners, uncover their many uses, and even offer tips on choosing and installing them.

The Hidden History Behind a Simple Closure

Snap fasteners, also known as press studs or poppers, may seem like a modern invention, but their roots trace back to the 19th century. Originally designed for practicality, they were first used in children's clothing to allow quick changes and prevent fumbling with buttons. Over time, their use expanded into military uniforms, workwear, and eventually high fashion. Today, they are not only valued for their utility but also embraced as design elements that add structure and visual interest to garments and accessories.

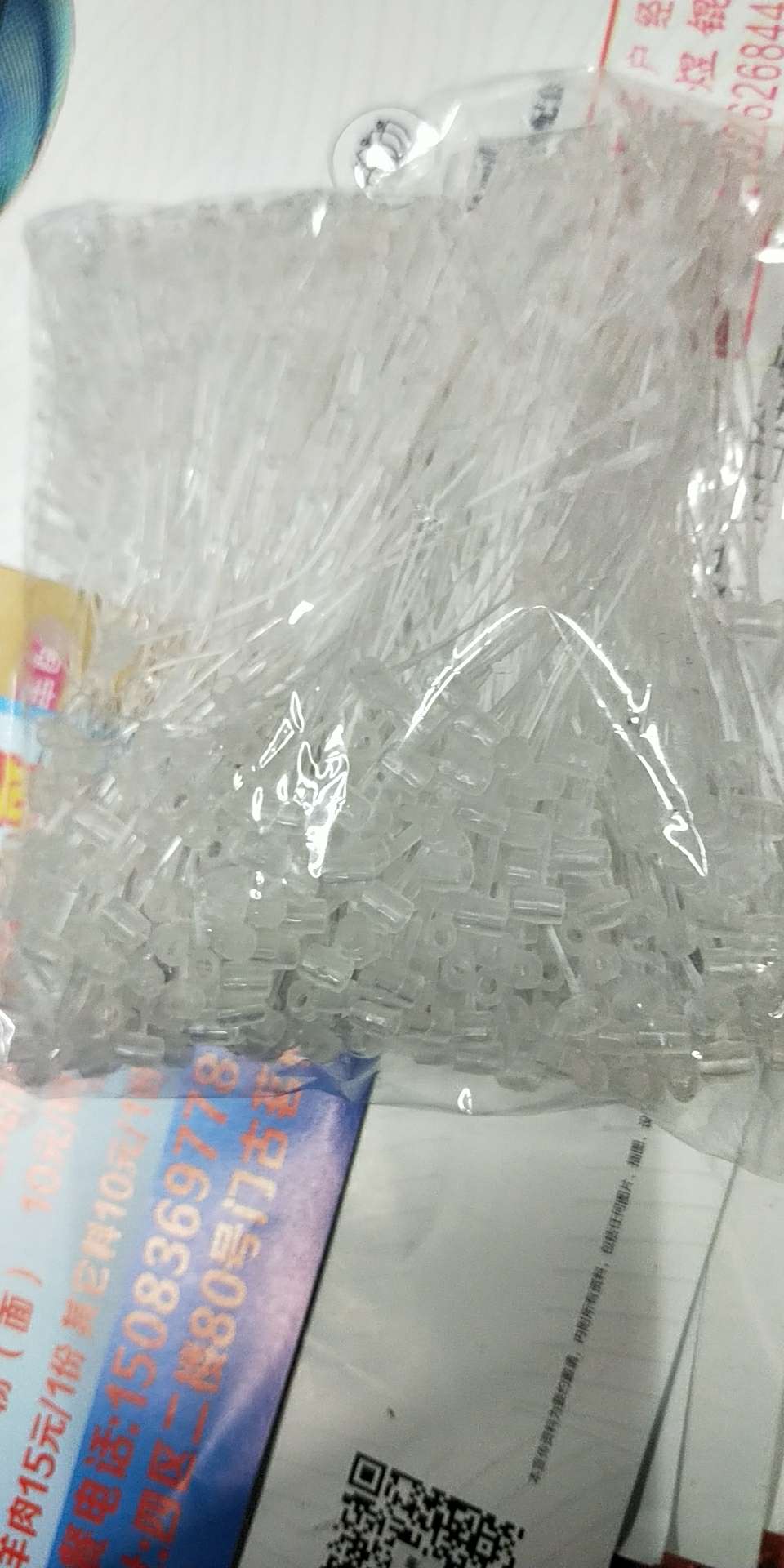

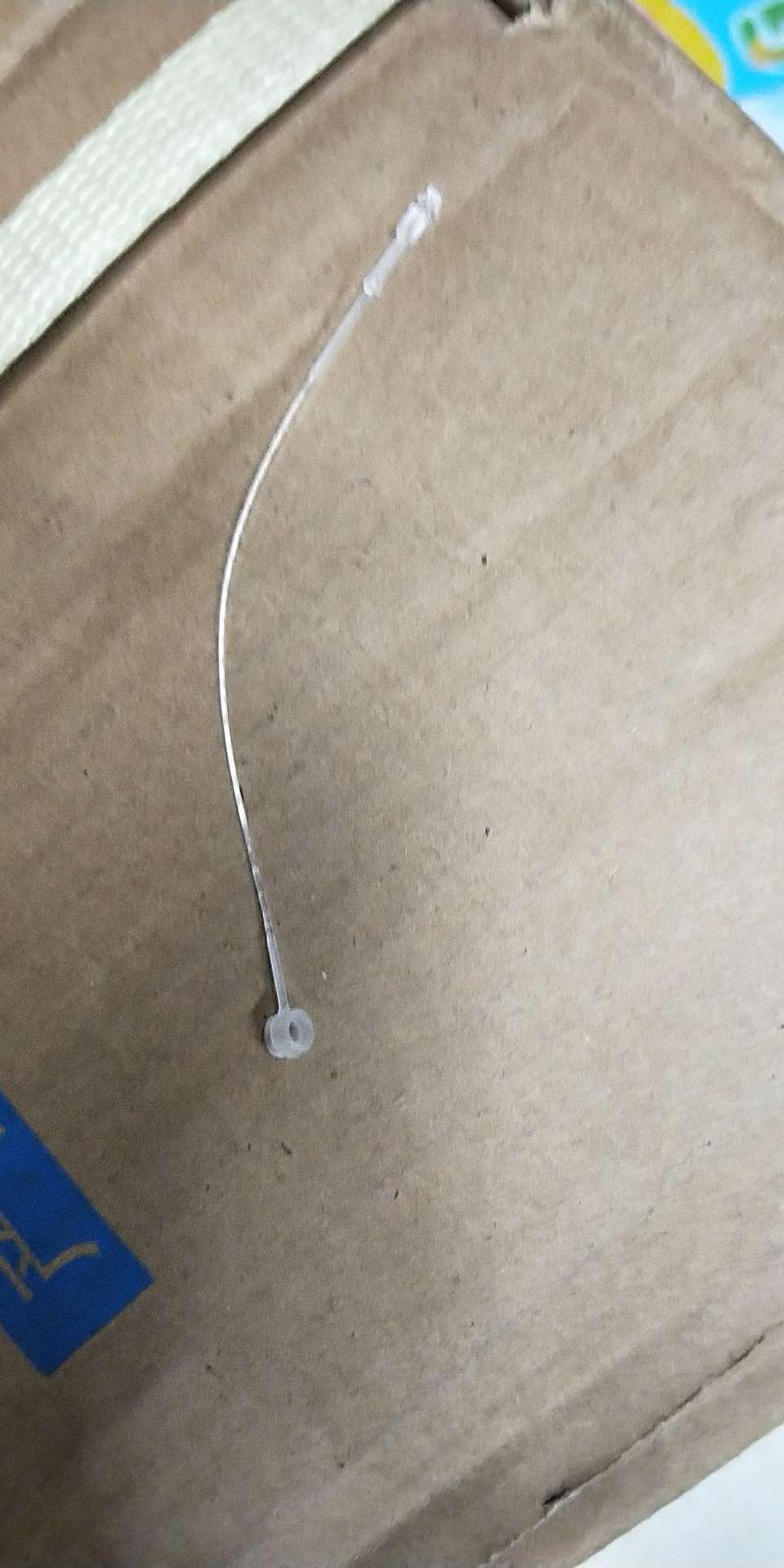

Understanding the Building Blocks of a Snap Fastener

At first glance, a snap fastener appears simple, but it is actually composed of three key parts: the socket (female component), the stud (male component), and the base that secures everything to the fabric. Each part must align perfectly to ensure a secure and smooth connection. The materials used can vary widely — from polished brass and nickel-plated steel to durable plastics and even eco-friendly bioplastics. Size matters too; small snaps suit delicate baby clothes while larger, sturdier versions hold up heavy-duty outdoor gear.

Why Designers Can’t Get Enough of Snap Fasteners

What makes a small metal or plastic closure so appealing to designers? The answer lies in its versatility. Snap fasteners offer a clean, minimalist look that blends seamlessly into both casual and formal wear. Their ease of use makes them ideal for items requiring frequent opening and closing — think jackets, bags, and even medical garments. Moreover, unlike zippers or buttons, they don't disrupt the fabric’s flow, making them perfect for sleek silhouettes and layered designs. They also support modular concepts, allowing users to detach or swap parts of a garment or accessory effortlessly.

Beyond Clothing: The Surprising Versatility of Snap Fasteners

While most people associate snap fasteners with apparel, their applications extend far beyond fashion. Outdoor enthusiasts will recognize them on tents, raincoats, and backpack flaps, where durability and weather resistance are essential. In industrial settings, they secure protective covers on machinery or help fasten medical device straps. Craft lovers adore them for DIY projects like handmade pouches, quilted toys, and custom tote bags. Even interior designers have found creative ways to integrate them into curtain tiebacks and upholstery details.

Choosing the Right Material for Your Project

Selecting the appropriate material for your snap fastener depends on the intended use and environment. Brass and copper options provide classic elegance and long-lasting strength, making them popular choices for premium garments. Nylon and polyurethane variants offer flexibility and water resistance, perfect for sports and outdoor gear. Zinc alloy snaps resist corrosion and maintain structural integrity under pressure, which explains their prevalence in industrial equipment. Meanwhile, sustainable alternatives made from recycled or plant-based materials are gaining traction among eco-conscious brands and consumers.

Installation Made Easy: From Tools to Troubleshooting

Installing snap fasteners might sound daunting, but with the right tools and technique, anyone can do it at home. Manual snap pliers are affordable and easy to find, making them suitable for small-scale projects or occasional use. For frequent installations, electric or hydraulic presses offer greater efficiency and consistency. The process typically involves marking the fabric, punching a hole, and pressing each half of the snap into place. If your snaps aren't clicking securely or seem misaligned, double-check your tool pressure and alignment. Sometimes, switching to a heavier-duty snap or reinforcing the fabric with interfacing solves the issue.

The Brands Behind the Snap: Who Ensures Quality?

Behind every reliable snap fastener is a brand committed to precision and performance. Leading manufacturers invest heavily in quality control, testing each batch for tensile strength, corrosion resistance, and durability under stress. While names like Prym, YKK, and Kam Snap are well-known in the industry, countless other companies produce high-quality alternatives tailored to specific markets. When sourcing snaps, consider factors like minimum order quantities, customization options, and certifications such as ISO standards. Partnering with a reputable supplier ensures your product meets both functional and aesthetic expectations.

What’s Next for the Snap Fastener?

As technology and sustainability shape the future of design, the snap fastener continues to evolve. Innovations like magnetic closures inspired by snap mechanisms are emerging in smart clothing and wearable tech. Biodegradable and compostable snap materials are being developed to reduce environmental impact. Additionally, modular fashion movements championing repairability and customization are breathing new life into this timeless fastening solution. Whether you're a fashion designer, engineer, or hobbyist, one thing is certain — the snap fastener isn't going anywhere anytime soon.