What Are Snap Fasteners? A Complete Guide to Types, Uses & Benefits

It’s 7 a.m., and the soft click of a snap closing on your baby’s onesie marks the start of the day. Later, as you zip up your hiking jacket against a sudden mountain downpour, your fingers instinctively secure the cuff with a firm press — another quiet victory for a tiny but mighty component. These moments may seem ordinary, yet they’re powered by an unsung hero of functional design: the humble snap fastener.

More Than a Closure: The Quiet Genius Behind the Snap

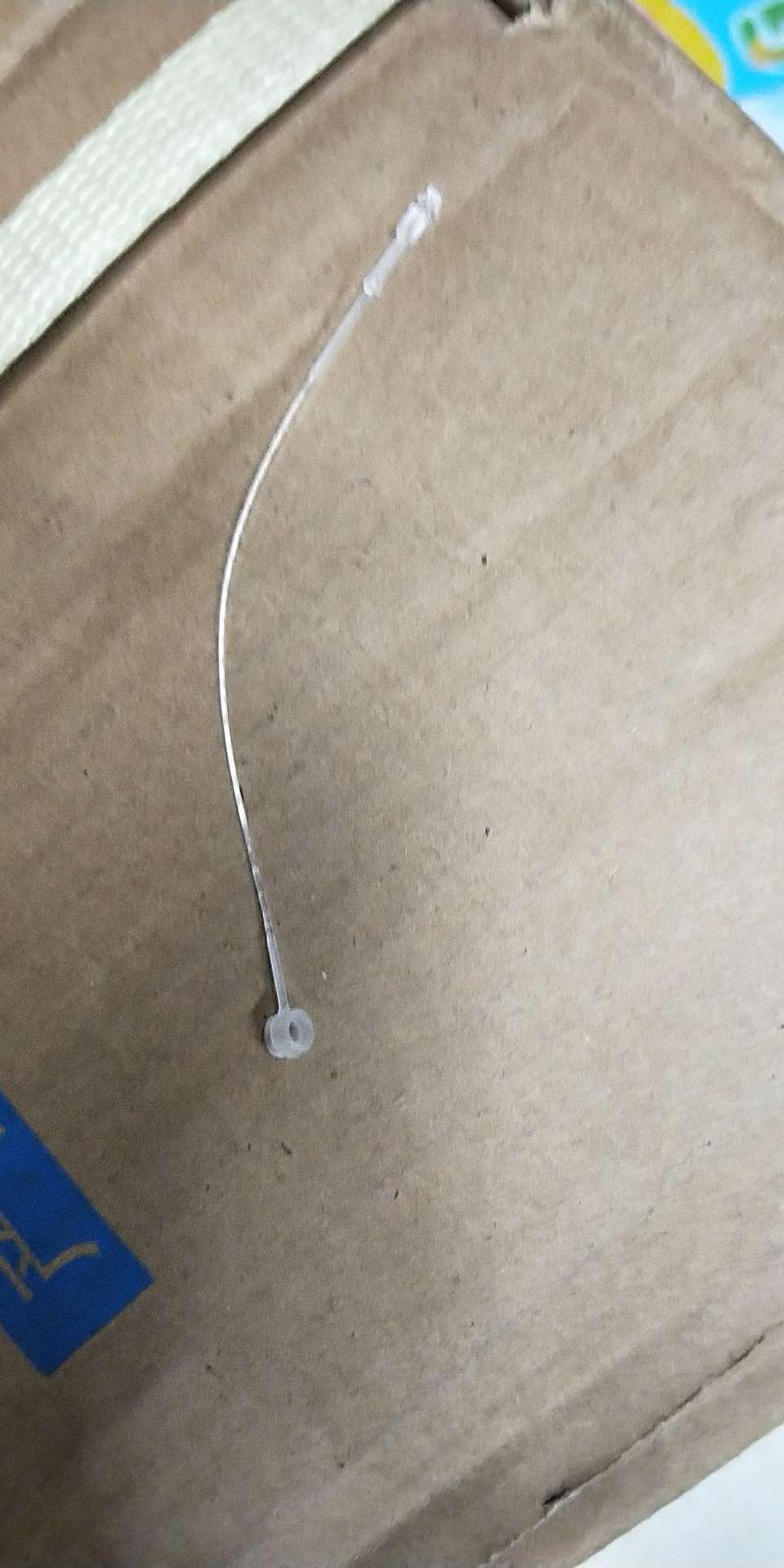

Beneath their unassuming appearance lies a marvel of micro-engineering. A snap fastener operates like a miniature mechanical joint — two interlocking halves that engage with precision and release under deliberate force. Think of it as a magnetic neuron in fabric, transmitting intent through touch. One half features a dome-shaped stud; the other, a socket designed to receive it with a satisfying “snap.” Together, they form a bond that’s both secure and reversible.

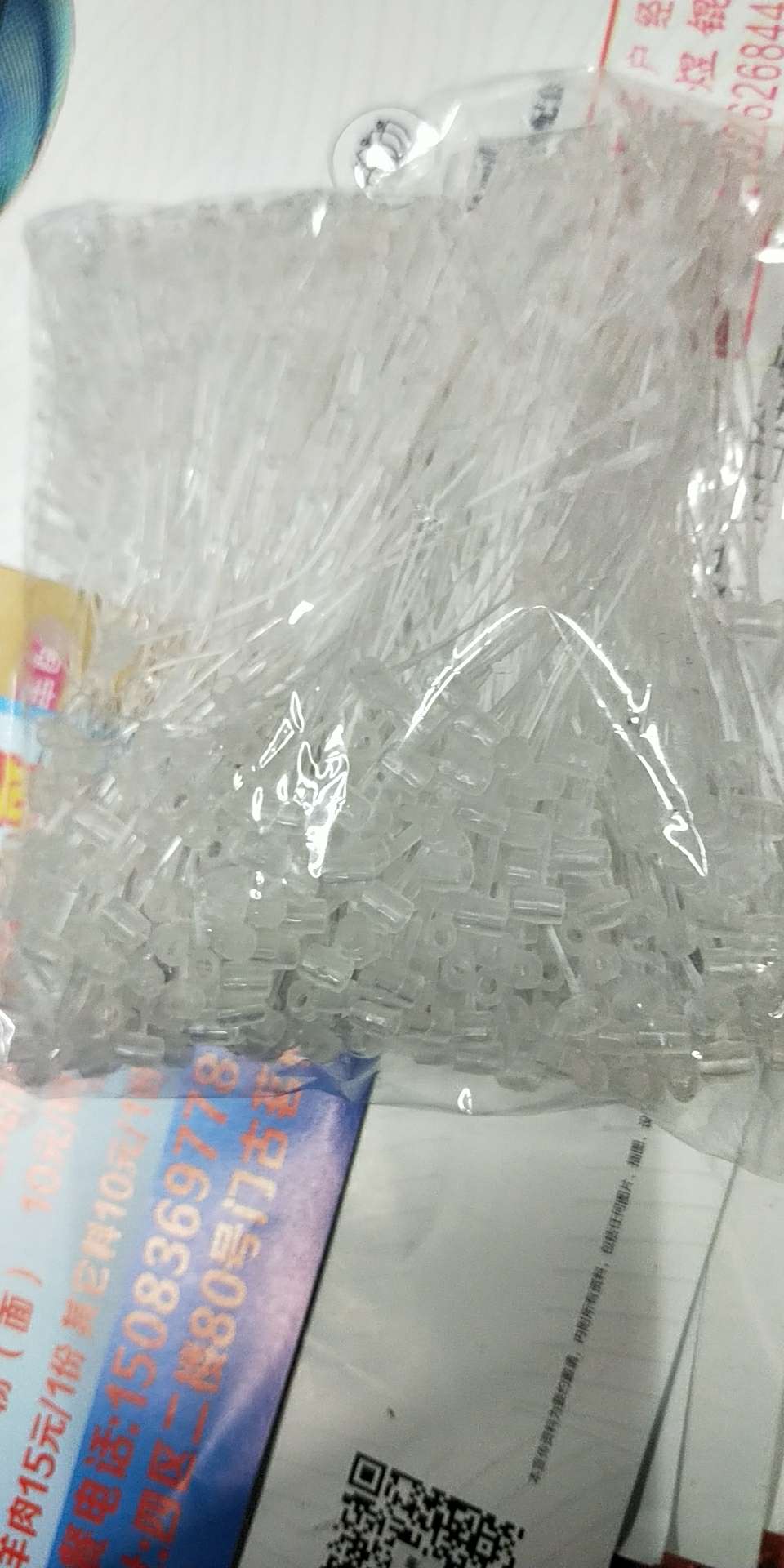

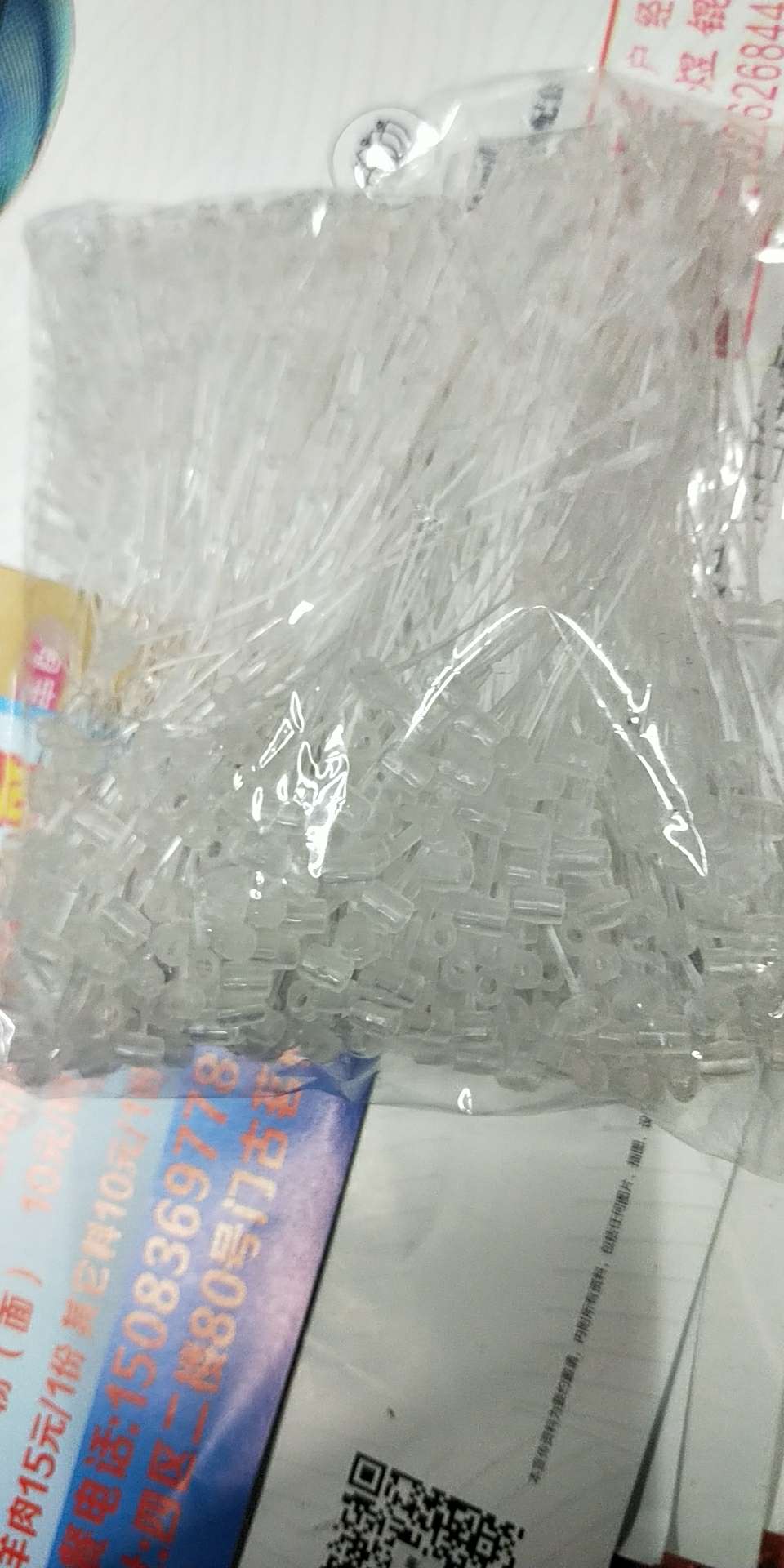

Materials play a crucial role in performance. Metal snaps, often made from brass or nickel-plated steel, offer durability and a premium feel, ideal for denim and outerwear. Plastic and resin variants provide flexibility and safety, especially important in children's clothing where sharp edges are a concern. Each choice reflects a balance between strength, weight, and tactile experience — a silent dialogue between designer, wearer, and environment.

The Family of Snaps: Designed for Every Purpose

You might not notice them all, but different snaps serve distinct roles across industries. Take the classic double metal snap — a staple on jeans and workwear. Its rugged construction withstands daily wear, holding firm even after hundreds of openings. Then there’s the plastic ball-head snap, commonly found in infant garments. Softer and safer, it prevents skin irritation while allowing caregivers to change diapers swiftly, one-handed.

In high-end fashion, hidden snap systems disappear into seams, preserving clean lines and minimalist silhouettes. These internal closures maintain elegance without sacrificing security — a favorite among trench coat designers who value both form and function. On the opposite end of the spectrum, oversized heavy-duty snaps anchor tactical vests, tool pouches, and outdoor backpacks. Built to endure extreme conditions, these powerhouses handle stress loads that would defeat standard closures.

Function Meets Inclusion: Rethinking Wearability

Snap fasteners do more than keep clothes closed — they enable independence. For individuals with limited dexterity, arthritis, or disabilities, snaps offer a dignified alternative to buttons or zippers. With one smooth motion, a garment can be secured, promoting autonomy in dressing routines. This makes them essential in adaptive clothing lines, where thoughtful design translates directly into quality of life.

They also act as connectors in modular fashion. Designers are increasingly exploring removable sleeves, collars, or liners held together by snaps, turning a single jacket into multiple configurations. In emergency response gear, rapid deployment is critical — firefighters and medics rely on snap-equipped uniforms for swift donning under pressure. Seconds matter, and snaps deliver speed without compromise.

From Utility to Statement: Snaps as Design Language

Fashion thrives on detail, and snaps have evolved beyond utility into expressive elements. Rows of decorative snaps march across lapels or pockets, creating rhythm and texture. Some brands use colored domes or custom shapes — heart-shaped, star-tipped, or engraved — turning fasteners into signature accents. In streetwear, exposed snaps signal functionality with flair, hinting at utility roots while adding visual interest.

Designers like Yohji Yamamoto and Maison Margiela have long embraced visible hardware, letting snaps become part of the aesthetic narrative. When arranged artistically, they transform from mere closures into storytelling devices — bold, intentional, and undeniably cool.

Choosing the Right Snap: A Designer’s Invisible Equation

Selecting the perfect snap isn’t guesswork — it’s a calculated decision rooted in context. Consider tension requirements: a baby romper needs gentle, flexible snaps that won’t irritate delicate skin, whereas a motorcycle seat cover demands industrial-grade components resistant to vibration and weather exposure.

Environmental resilience matters too. Coastal environments expose fabrics to salt spray; marine-grade stainless steel snaps resist corrosion far better than plated alternatives. Meanwhile, manufacturing processes influence choices — ultrasonic welding works well for synthetic textiles, while traditional stitching suits cotton-heavy materials. Understanding these variables ensures longevity and user satisfaction.

The Future Is Snapped: Innovation Woven In

As smart textiles emerge, so does a new frontier for snap technology. Imagine conductive metal snaps serving as data or power connectors in wearable health monitors — seamlessly linking sensors to hubs without wires. Researchers are already experimenting with such integrations, turning everyday closures into interactive nodes.

Sustainability is driving change too. Bioplastics derived from cornstarch or algae are entering the market, offering eco-conscious alternatives to petroleum-based resins. And with 3D printing enabling on-demand production, personalized snap designs — shaped to fit unique garments or branded with logos — are becoming more accessible than ever.

The snap fastener, once overlooked, now stands at the intersection of tradition and innovation. It’s proof that true design excellence often hides in plain sight — small, simple, and perfectly formed.